How to choose the right materials for your custom vinyl stickers

When it comes to creating custom vinyl stickers, choosing the right materials is crucial. Whether you are designing stickers for personal use or your business, selecting high-quality materials will ensure that your stickers look great and last long. In this article, we will guide you through the process of choosing the right materials for your custom vinyl stickers. We will cover important factors such as vinyl type, adhesive, laminate, and finish options. So let's dive in and find out how to make your stickers stand out!

Understanding Vinyl Types

Before we delve into the different types of vinyl, let's quickly understand what vinyl is and why it is a popular choice for stickers. Vinyl is a synthetic material known for its durability, flexibility, and ability to withstand various environmental conditions. It is widely used for stickers due to its water resistance, UV resistance, and long-lasting adhesive properties.

When it comes to vinyl types, there are two main categories: calendared vinyl and cast vinyl.

- Calendared Vinyl: Calendared vinyl is created by passing PVC through rollers, resulting in a flexible and economical material. It is ideal for short-term applications such as promotional stickers or indoor signage. However, it is not recommended for long-term outdoor use as it may shrink or fade over time.

- Cast Vinyl: Cast vinyl is produced by pouring liquid PVC into a thin sheet while keeping it in a liquid state. This process creates a more durable and long-lasting material compared to calendared vinyl. Cast vinyl is perfect for outdoor applications or situations where longevity is essential, such as car decals or window graphics. It retains its shape even on uneven surfaces.

Choosing the Right Adhesive

The adhesive used on vinyl stickers plays a crucial role in their performance and longevity. Different adhesives are designed for specific applications, so it is important to consider the intended use of your stickers.

Let's explore the three commonly used adhesive types:

- Permanent Adhesive: As the name suggests, permanent adhesive offers a strong bond, making it difficult to remove the sticker once applied. It is suitable for long-term use on surfaces such as vehicles or products.

- Removable Adhesive: Removable adhesive allows the sticker to be easily peeled off without leaving any residue behind. This type of adhesive is ideal for temporary applications or situations where you may want to reposition or remove the sticker without damaging the surface.

- Static Cling: Static cling adhesive utilizes static electricity to adhere to smooth surfaces such as glass. It can be easily removed and reapplied without leaving residue. Static cling stickers are commonly used for window displays or temporary promotions.

Considering Lamination

Lamination is the process of applying a thin protective layer over the vinyl sticker. It enhances durability, UV resistance, and overall longevity. Depending on your specific needs, you can choose between two popular lamination options:

- Gloss Lamination: Gloss lamination adds a shiny and reflective surface to the sticker, giving it a vibrant and eye-catching appearance. It not only protects the sticker from scratches and fading but also enhances the colors and design.

- Matte Lamination: Matte lamination provides a non-reflective finish, giving the stickers a more subtle and sophisticated look. It reduces glare and is great for designs that require a softer appearance.

Finishing Touches

In addition to the vinyl type, adhesive, and lamination, there are various finishing options you can consider to further customize your stickers:

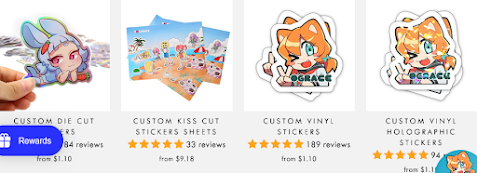

- Die-Cutting: Die-cut stickers are custom-shaped stickers that can be cut into any desired shape or design. This option adds uniqueness and helps your stickers stand out.

- Kiss-Cutting: Kiss-cutting is a process where the sticker is cut through the vinyl layer but not the backing paper. This allows for easy peeling and individual sticker removal.

- Foil Stamping: Foil stamping involves adding metallic foils to the sticker, creating a shiny and luxurious effect.

- Embossing or Debossing: Embossing raises the design elements, while debossing creates a depressed or indented effect. These techniques add a tactile dimension to your stickers.

Conclusion

Choosing the right materials for your custom vinyl stickers is essential to achieve the desired look, durability, and longevity. Consider the vinyl type, adhesive, lamination, finishing options, and your specific needs to make an informed decision. Remember, high-quality materials result in high-quality stickers that will make a lasting impression. So go ahead, get creative, and design your own custom vinyl stickers!

Comments

Post a Comment